Portfolio

Who am I?

I am JJ Vinet, a husband, professional skier, designer, and maker. I have an extensive background in skiing and design. Today I am a free skier who works with different companies within the ski industry. My background in the ski industry is diverse. I have competed in ski racing, park and pipe skiing, the Subaru Free Skiing World Tour and the Free Ride World Qualifier series. I formally worked as a professional ski patroller for Revelstoke Mountain Resort and when I am away from mountain, I am a business owner. I have been running my own architectural design business for 10 years where I focus on modern residential design.

An edit with some soft snow around Revelstoke BC.

Skier

Adolescence / Park skiing

I was first put on snow at the age of two. I learned ski fundamentals ski racing and ski jumping. After I aged out of local ski programs, I headed into the terrain park where became a self taught park skier. I competed in half pipe, big air, and Slopestyle.

Early Terrain park days

Early Terrain Park days

Finding snow in July

Crowd pleasers for days

Big Mountain

The prairies of Alberta helped build on snow skills and a passion for skiing that would lead me to the mountains. As I got older and my educational career brought me closer to the mountains I started competing in competitive big mountain skiing. I have competed around the world on the Subaru Freesking World Tour, Freeride world tour and Freeride World Qualifier Series.

Chilean Free Ski Championships

Chilean Free Ski Championships

Chilean Free Ski Championships

Ski Patrol

My big mountain purists led me to a professional career in ski patrol at the world renowned Revelstoke Mountain Resort. Here I was involved with snow safety, mountain rescue, day to day on slope operations, and I was a first responder for any on mountain issue. Through patrol, I really started to see how gear was a tool to be used. Good gear lasted, and cheap gear got destroyed.

Snow Science: Rutsch Block During my ski patrol days

Avalanche Control: Cornice debris from explosive control using a trunk line.

Lift evacuation: Pre season training at Revelstoke Mountain Resort

Ski Patrol: Making sure to send even in uniform. We move to the mountains to ski so always try to have fun on snow even if you're working.

Professional

As I started building relationships within the ski community, I left patrol to focus on my true passion free skiing and design. I started working with brands as an athlete and ambassador. I create content for print, social media, and web use. I regularly shoot with professional photographers from around the world who are able to capture the essence of skiing. Working with companies created a direct line of communication to those making the products we use in the mountains. This opened a dialog with industry professionals as I had direct contact with designers and engineers who valued my professional insight and critique.

Published work from photographer Ryan Creary

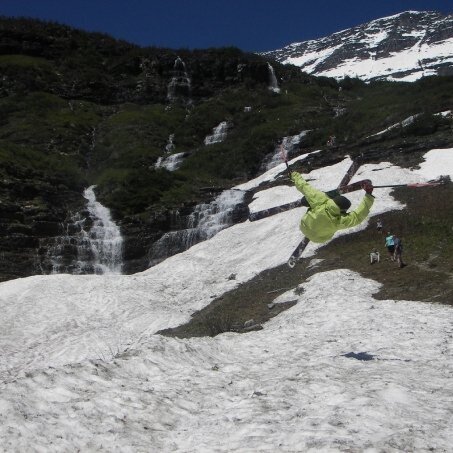

Published photo by Brent Benson of me skiing over a waterfall

Close up of the previous waterfall image.

The image used by Revelstoke Mountain Resort on their poster

Designer

In school I excelled in the arts and in the wood shop. This led me to taking up design studies through high school where I was an honours student in drafting and design. After high school I attended collage where I became a Jr. Architect / Architectural Technologist. I graduated from SAIT Polytechnic, a technical institution in the field of Architectural Technologies with honours. After college I continued my education by attending the University of Calgary where I studied in the Masters of Architecture program in the faculty of Environmental design. After University I made my move westward to Revelstoke BC where. This profession has given me the skill sets to constantly analyze the world around me. I am always sketching design ideas and working through new concepts.

Sketching: Idea development

3D design Creating 3D worlds from 2D plans

Construction documentation: Creating technical drawings to communicate how intricate designs should be assembled

Completed Design: Thoughtful design and careful execution lead to beautifully built spaces.

My design business has allowed me to work with clients, industry professionals, trades people, and material suppliers. I have learned to navigate complicated building process while executing intricate designs. I work with clients through the initial design phase utilizing sketching, 3D modelling and CAD software. The process takes preliminary sketches and develops them into working drawings that the different trades are able to use during the build process.

How did I integrate my ski and design careers together?

After my formal education, I headed west to the mountains and ended up in Revelstoke BC where I gained employment with Revelstoke Mountain Resort as a professional ski patroller. My drive as a skier grew as I learned more facets of the ski industry. After enough time in the field I built relationships with industry professionals. One of the first major relationships I built was with Hans Smith, who was the CEO and head designer at Armada Skis. Han’s and I would talk for hours about ski tech and design. After a few years I joined Armada as an ambassador where I was being asked for my insight into ski design.

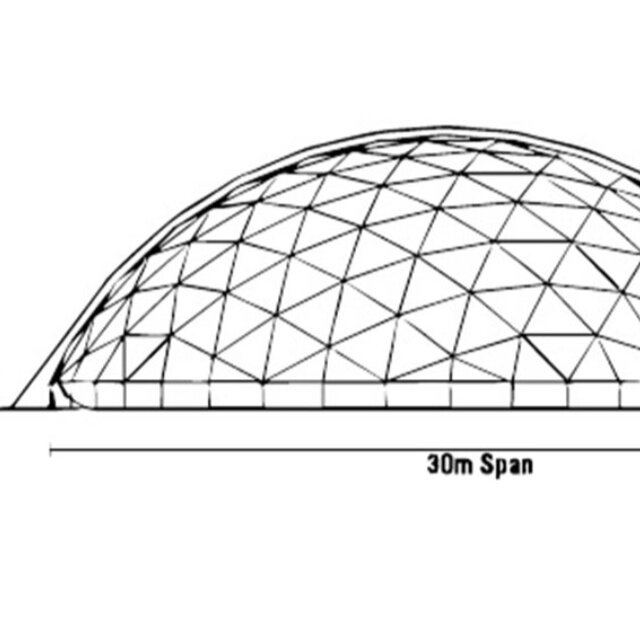

One of my contributions to Armada was the idea of combining a low lying geodesic dome to create a new ski core profile.

Insight: Roman Arch Utilizes structure

Insight: Bio mimicry acknowledges natural design and incorporates it into the manufactured process. I looked towards the design of eggs to incorporate a shallow dome within ski core profile to transfer loads throughout the ski more smoothly.

Insight: Geodesic domes have unprecedented strength. The faceted design simplifies complex shapes.

Above are some images that inspired a new ski core profile. My goal was to combine the strength of a geodesic dome over the length of a ski. The idea of a squished egg started to formulate what this might look like in a ski core.

CADD DESIGN: I took the ideas from above and formulated them into a sketch for the team at Armada. This is a screen shot of my cad work I presented to Armada. There were concerns about executing the manufacturing of this design as a smooth CNC’d path, but they were interested in the concept and would look to other methods that would achieve a similar result.

Product Execution: After product testing different designs, Armada rolled out with a new core design featured in their “Tracer” ski. The design focused on a more drastic side wall taper that mimicked the idea of the previously designed elongated and squished geodesic dome. It was great to collaborate on a new shape within the ski industry.

New Companies and new designs

I took an opportunity to move on to something new and too work with Rocky Mountain Underground. As a small ski company based out of Breckenridge Colorado, I was able to prototype new designs and got first had experience building skis.

Preliminary ski design: This design was a preliminary shape I came up with after skiing 4FRNT’s Renegade and Amrada’s Magic J, Norwalk and Bubbas. All skis had elements that made them unique, but all lacked elements others provided. I wanted to try my hand at coming up with a new shape that addressed the elements I was missing. This process would give me a first hand experience playing with geometries, flex patterns, material science and product manufacturing.

Preliminary design: I really enjoyed a full rocker profile I experienced in the Armada Bubba and 4Frnt Renegade so focused the rocker profile of my new design around those two skis. This shape left little contact under foot and made for fast and aggressive pivoting on snow. Now I would get to play with different core materials and fibreglass layups to try different flex patterns.

Manufacturing: I had the opportunity to design molds for the shapes I wanted to test. I learned about the manufacturing process at a basic level and got a taste for what worked and what didn’t.

Prototyping: I repurposed old molds to try new shapes. The Above image shows the line of the new profile on an old mold.

Prototyping: The profile was transferred using low tech print outs of the shape. This made for relatively fast turnaround when prototyping a new shap.

Prototyping: I used a hand router and sanding blocks to finalize a preliminary rocker profile. This was less expensive than a CNC and reused old unused designs.

Prototyping: I’ve milled my own core material. After purchasing pre manufactured cores online, I saw the need to manipulate material properties by making my own cores.

Prototyping: Here I am testing different layups of different wood.

Prototyping: I laminated and milled my own profiles.

Prototyping: I tested different core profiles with a similar shapes. This allowed me to feel how a ski would flex differently while having the same turn radiuses and rocker profiles.

Prototyping: I’ve glued my own edges

Prototyping: And I have pressed my own skis.

Prototyping: I’ve cut out my own skis and finished my own bases.

Prototyping: Tip close up

Product Testing: The best part is on snow trials.

Product Testing: I’ve seen what works, and what doesn’t and have learned from my mistakes.

Product Testing: I continue to tinker with shapes and play with new designs.

Product Testing: I’ve take old designs and made new skis to rapid prototype different shapes.

Product test prototype skis.

Maker

I am a maker at heart and I am always thinking about design. I like to get a hands on feel with materials and am always building something, whether its a renovating my home, designing and building custom furniture, tweaking my gear or just playing in the wood shop to see if something is possible. If I’m not building something physical, Im often creating concept work with CAD, sketchbooks, and 3D software.

Furniture: Building dining tables can be similar to ski design at times.

Furniture: How things are assembled effect how they are used.

Furniture: Materials have many properties, wood can be strong and also be inviting with its natural tones.

Shown above is a solid wood dining table I designed and built by laminating reclaimed wood together. The goal was to design a minimalist table without any substructure. The table is made of reclaimed cedar from the renovated home. The tables is a feature within the main living space.

Shown above is the process in which is designed and built custom stand up paddle board (SUP) paddles. These paddles use Canadian maple and Purple Heart.